Our Process

-

Upon returning from our customers, after delivering clean linen and picking up the soiled linen, our drivers unload the carts of soiled linen from the trucks int o the plant to be weighed in and sorted.

Upon returning from our customers, after delivering clean linen and picking up the soiled linen, our drivers unload the carts of soiled linen from the trucks int o the plant to be weighed in and sorted. -

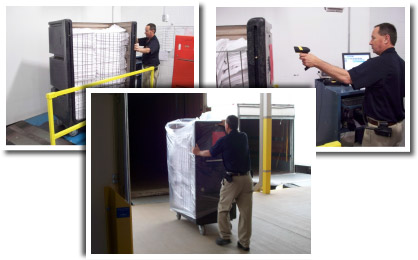

Once the linen carts are unloaded off the trucks, the carts are weighed and scanned in using infrared handheld scanning technology and the data is recorded to our computer software for records and tracking purposes per customer.

Once the linen carts are unloaded off the trucks, the carts are weighed and scanned in using infrared handheld scanning technology and the data is recorded to our computer software for records and tracking purposes per customer. -

After being weighed and scanned in, the linen carts are placed in a “cart dumper”, a machine created by E-Tech, Inc. to dump the carts onto a breakup table where our staff breaks open the bags and spreads the linen onto the sort deck conveyor to be sorted into individual bins per product.

-

As linen comes in all mixed together from the patient floors and medical facilities, it is necessary to sort the linen by product into individual bins so that the linens can be washed with the proper wash cycle (i.e. water temp, chemical scheme, wash time, etc.).

-

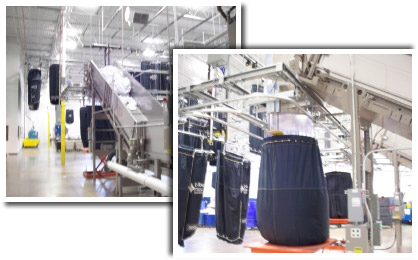

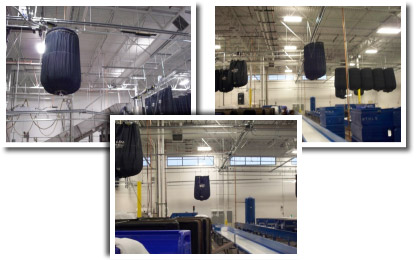

Utilizing state-of-the-art technology, our linen is sorted into bags that also weigh the linen as it is sorted and once the bag is full, it automatically leaves the sort station and is travels to the washer via a railing system in the rafters of our building.

-

Once sorted and inputted into the rail system, the slings of linen move automatically throughout the system without being prompted by an operator. After the sort process, the linen goes to be washed in one of our 2 tunnel washing machines. Our tunnel washers both have 8 modules and can hold up to 150 lbs. per load (per sling), washing linens through a series of chemicals to not only get the linen clean, but to sanitize the linen with an arsenal of 5 chemical treatments.

-

Once linen leaves the tunnel washers, it is dispensed into a press extractor which presses the water out of the linen in order to decrease dryer times. Once the water is extracted, the linen comes out in the form of a “cake” which is then loaded onto a trolly which takes the cake of linen to the dryer to complete the dry cycle.

-

The linen is automatically dispelled out of the dryer once it is complete and onto another conveyor belt which then takes the linen and dumps it into another sling to be transported to the processing machines that will press and fold the linen.

-

Based on the product and how it needs to be processed, the linen will automatically travel to the machine best suited to do so. When the sling of freshly clean and dried linen arrives at the “drop station”, our staff will dump the sling, releasing the linen into a cart or dump station to be processed.

-

After dumping the slings, trained staff will process each item, using the appropriate machinery to rapidly produce large quantities of linen in the timeliest manner to meet the needs of our customers. Some machines iron and fold items, and others just fold. Some items, however, still need to be hand folded.

-

Once the linen is processed by the machine, the linen is moved onto a long conveyor belt which transports the linen to the “carousel” which rotates around to allow staff the opportunity to pick what they need to fill orders. At this time, staff will take the linens from the carousel and put them into carts based on customers’ orders.

-

When the carts are filled, a delivery slip is attached to the cart with the customer’s name and quantity of each item in the cart based on the customer’s order. The cart is then covered with a plastic bag to maintain linen quality, weighed and scanned out to the customer, and then loaded onto the truck to be delivered.